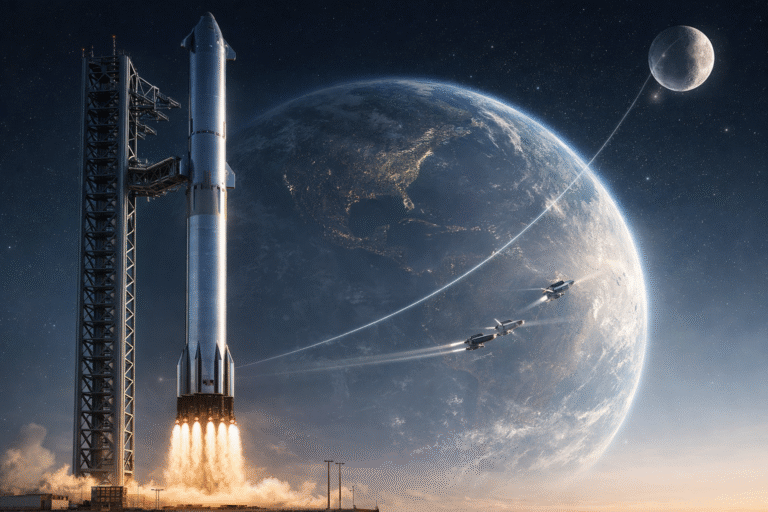

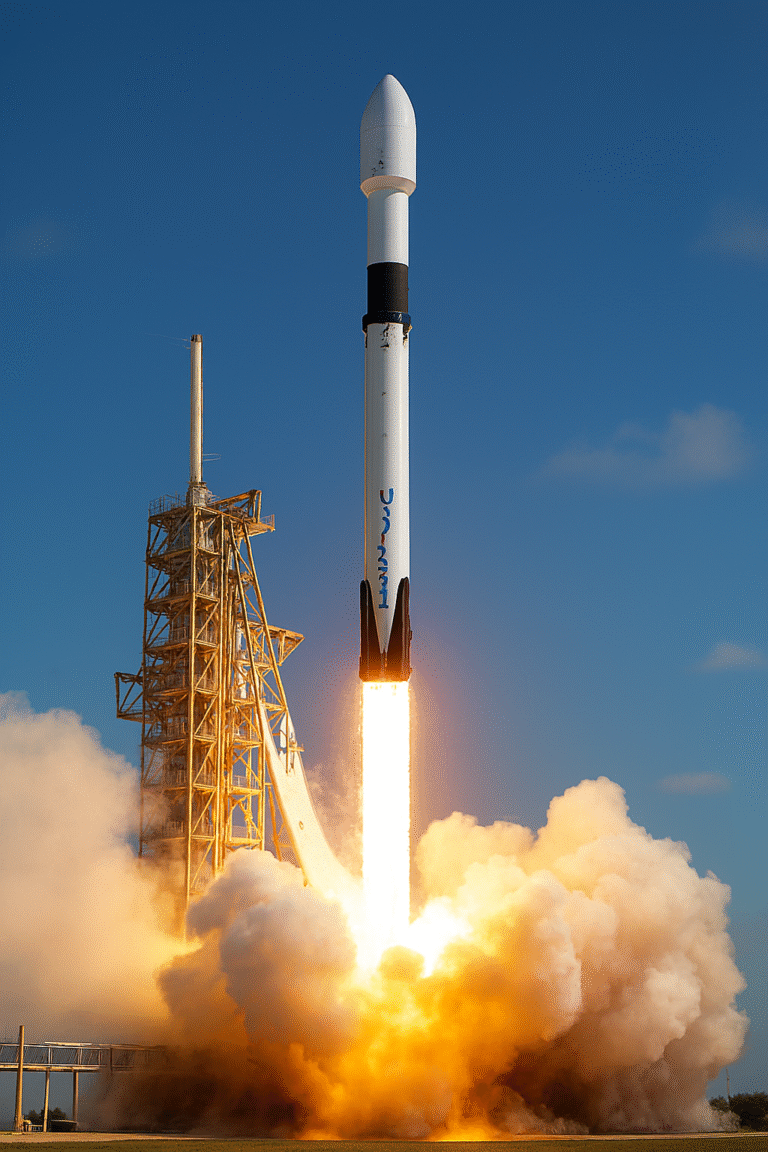

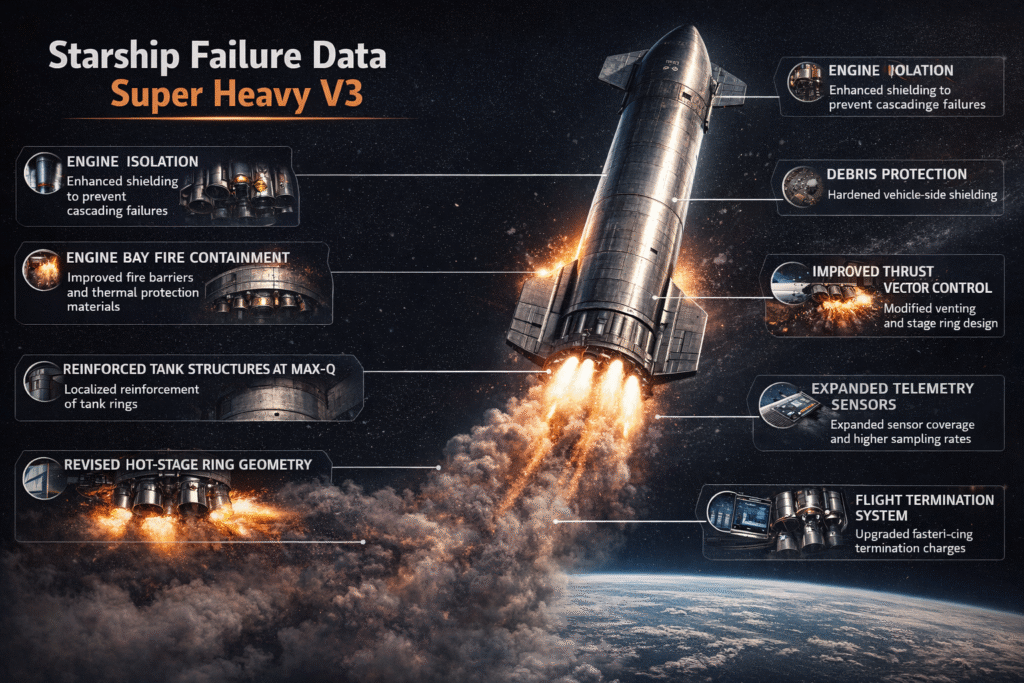

Starship failure data Super Heavy V3 is not a story of setbacks—it is a documented engineering process unfolding in real time.

Early Starship test flights did not always reach their planned mission objectives. However, each failure generated full-scale flight data that simulations and ground tests could never fully replicate. Instead of concealing these outcomes, SpaceX analyzed Starship failure data in depth using telemetry, high-speed imagery, onboard sensors, and FAA-reviewed mishap investigations.

The result of this approach is Super Heavy V3, the most refined booster variant to date—directly shaped by verified Starship failure data and evidence-based design changes.

How Starship Failure Data Shaped Super Heavy V3 Design

Starship failure data revealed how the system behaved under real aerodynamic loads, thermal stress, vibration, and cascading engine failures. These insights directly influenced structural layouts, software logic, engine bay protection, and safety systems on Super Heavy V3.

This was not theoretical optimization. Every change can be traced to observed behavior during flight.

Starship Failure Data Super Heavy V3 — Verified Design Lessons

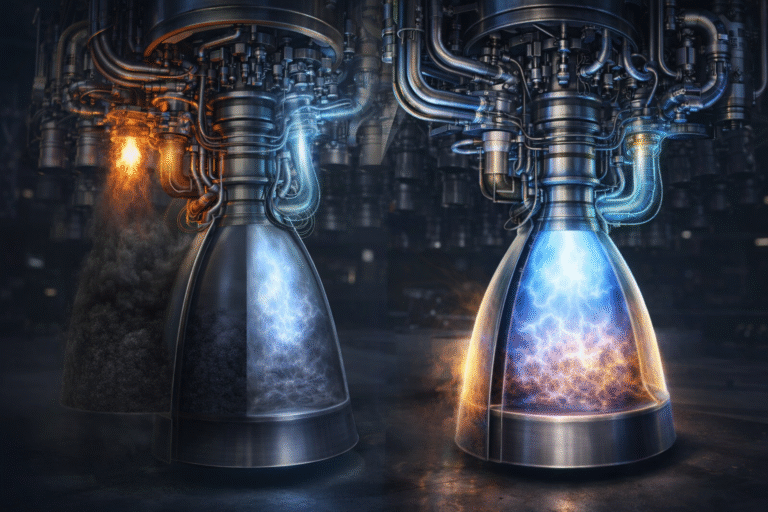

Lesson 1 – Starship Failure Data Revealed Engine-Out Limits in Super Heavy V3

Early integrated flights showed that multiple Raptor failures occurring close together caused thrust imbalance more rapidly than predicted. Starship failure data confirmed that debris and heat from one engine could impact adjacent engines.

Super Heavy V3 response:

Engine bay spacing, shielding geometry, and control response timing were revised to reduce cascading failures.

Lesson 2 – Engine Bay Fires in Starship Failure Data Drove Super Heavy V3 Changes

Onboard cameras and thermal sensors recorded persistent fires even after engine shutdown.

Response:

Improved fire isolation zones and enhanced thermal protection materials were introduced.

Lesson 3 – Flight Termination Lessons from Starship Failure Data Applied to Super Heavy V3

FAA-reviewed Starship failure data showed that the vehicle remained structurally intact longer than expected after loss of control.

Response:

FTS charge placement and redundancy were redesigned for faster tank rupture when required.

Lesson 4 – Structural Flexing Seen in Starship Failure Data Strengthened Super Heavy V3

Strain gauges recorded higher-than-expected flexing during Max-Q, especially near tank ring welds.

Super Heavy V3 response:

Localized reinforcements were added only where real stress concentrations were measured.

Lesson 5 – Hot Staging Risks Identified in Starship Failure Data Refined Super Heavy V3

High-speed footage showed exhaust plume interaction and pressure spikes during hot staging.

Super Heavy V3 response:

Hot-stage ring geometry and venting paths were modified.

Lesson 6 – Control Authority Loss in Starship Failure Data Improved Super Heavy V3 Software

Guidance data showed gimbal limits were reached sooner during uneven thrust conditions.

Super Heavy V3 response:

Updated thrust vector control logic and earlier fault detection thresholds.

Lesson 7 – Debris Impact Observed in Starship Failure Data Hardened Super Heavy V3

Post-flight inspections revealed debris and plume interaction with vehicle surfaces.

Super Heavy V3 response:

Improved vehicle-side shielding coordinated with launch pad upgrades.

Lesson 8 – Telemetry Gaps in Starship Failure Data Expanded Super Heavy V3 Sensors

Some failures evolved faster than existing telemetry sampling rates could capture.

Super Heavy V3 response:

Expanded sensor coverage and higher data sampling frequency.

Lesson 9 – Why Starship Failure Data Recalibrated Super Heavy V3 Engineering Margins

Several failure modes were not predicted by simulations.

Super Heavy V3 response:

Design margins were recalculated using real Starship failure data rather than purely modeled assumptions.

Conclusion (Optimized)

Starship failure data Super Heavy V3 represents engineering transparency at full scale.

Each failure exposed a real limitation. Each limitation led to a documented design response. Super Heavy V3 exists not because earlier vehicles succeeded—but because they failed in ways engineers could measure, understand, and correct.

This is how launch systems mature.

Failure data today reduces mission risk tomorrow.