In a stunning display of resilience and rapid innovation, SpaceX has announced the complete stacking of Super Heavy Booster 19, the second Version 3 (V3) prototype of its groundbreaking Starship system. The milestone, achieved on Christmas Eve at the company’s Starbase facility in Boca Chica, Texas, comes just over a month after a destructive anomaly sidelined its predecessor, Booster 18. This swift turnaround underscores SpaceX’s relentless pursuit of reusable spaceflight technology, keeping the ambitious Starship program on track for its twelfth orbital flight test in early 2026.The announcement came via a concise post on X (formerly Twitter) from SpaceX’s official account: “Stack complete.” Accompanying the message was a striking photograph capturing the gleaming 71-meter-tall stainless steel behemoth standing tall inside Mega Bay 1, surrounded by scaffolding and bustling teams. The image reveals the booster’s sleek, cylindrical form, topped with its integrated hot staging ring and supported by intricate structural elements, a testament to the engineering prowess that has become synonymous with Elon Musk’s aerospace venture.This achievement is particularly remarkable given the recent setback. On November 21, 2025, Booster 18—the first V3 Super Heavy—suffered a critical failure during a gas system pressure test at the Masseys test site. The incident, which SpaceX described as an “anomaly” involving no propellant or installed engines, resulted in significant damage, including a rupture likely caused by the explosion of a composite overwrapped pressure vessel (COPV).

Fortunately, no injuries were reported, as personnel maintained a safe distance during the operation. The booster was subsequently scrapped, with teams meticulously removing sections like the liquid methane (LCH4) tank and common dome to clear the way for repairs to the thrust simulator stand.Despite the loss, SpaceX wasted no time pivoting to Booster 19. Stacking operations began on November 27, starting with the common dome and lower ring sections in Mega Bay 1.

Over the following weeks, workers welded the liquid oxygen (LOX) tank to the engine section, added methane tank barrels, and integrated the forward dome. By December 20, all barrel sections were in place, culminating in the final assembly using internal bridge cranes and a ring stand. Remarkably, the entire process took just 25 days—half the 42 days required for Booster 17, the last Version 1 booster—highlighting SpaceX’s accelerated production cadence. Source (nasaspaceflight.com)

Booster 19 represents a pivotal evolution in the Starship architecture. As part of the Block 3 design, it incorporates numerous upgrades aimed at enhancing performance, reliability, and reusability. Key features include stretched propellant tanks for increased capacity, Raptor 3 engines that promise higher thrust and efficiency, and an integrated hot staging ring for smoother separation during ascent.

The booster also boasts redesigned grid fins—approximately 50% larger and constructed from stronger materials—to improve control during descent and landing maneuvers.

These enhancements are crucial for achieving SpaceX’s goals of rapid reusability, where boosters could theoretically fly multiple times per day, dramatically reducing the cost of space travel. Parallel to Booster 19’s progress, Ship 39—the upper stage counterpart for Flight 12—is advancing in Mega Bay 2. Fully stacked since November, it recently underwent a COPV swap, incorporating lessons from prior failures to bolster safety.

Ship 39 features docking ports and can be configured as a tanker vehicle with added probes, enabling in-orbit refueling—a cornerstone for long-duration missions to the Moon and Mars.

Both vehicles are slated for cryogenic proof testing at Masseys, followed by static fire campaigns to validate their systems.The Starship program, envisioned as a fully reusable spacecraft capable of carrying up to 100 passengers or 150 metric tons of cargo, has seen remarkable strides since its inception. From the early hopper tests in 2019 to the successful booster catch during Flight 5 in October 2024, SpaceX has iteratively refined the design through a “fail fast, learn fast” philosophy. The V3 upgrades build on these successes, addressing challenges like thermal protection during reentry and precise orbital insertions. With Flight 12 targeted for the first quarter of 2026—potentially as early as February or March—the mission will debut the Block 3 vehicles, utilize the upgraded Pad 2 at Starbase, and incorporate Raptor 3 engines for the first time.

This rapid recovery from the Booster 18 incident exemplifies SpaceX’s operational agility. As Elon Musk has often emphasized, setbacks are integral to innovation in rocketry. In a recent update, SpaceX reiterated that the Starbase team plans to align Booster 19’s testing with the original schedule for the V3 vehicles and ground systems, ensuring no major delays to the program.

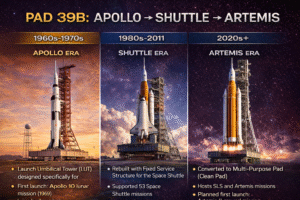

The company’s ability to stack a new booster in under a month not only mitigates the impact of the anomaly but also sets a new benchmark for manufacturing efficiency.Looking ahead, Starship’s success is pivotal for NASA’s Artemis program, where it will serve as the Human Landing System for lunar missions, and for Musk’s vision of establishing a self-sustaining city on Mars by the 2030s. With contracts from NASA worth billions and partnerships for satellite deployments, the stakes are high. Flight 12 will test critical elements like in-flight engine relights, heat shield durability, and perhaps even a booster catch attempt, paving the way for crewed flights and beyond-Earth operations.As the world celebrates the holidays, SpaceX’s “Christmas miracle” at Starbase serves as a reminder of human ingenuity’s boundless potential. From the ashes of Booster 18 rises Booster 19, a symbol of perseverance that brings us one step closer to making multi-planetary life a reality. With eyes on the stars, SpaceX continues to push the envelope, inspiring a new era of exploration.