Super Heavy V3 vibration control is one of the most extreme engineering challenges ever attempted in rocket science. When SpaceX ignites 33 Raptor engines at the same moment, the booster is exposed to sound and vibration forces so violent that even steel can fail within seconds. The shocking truth is that liftoff is not the most powerful moment of flight—it is the most dangerous one.

So how does the most powerful rocket ever built survive its own strength?

The violent reality of a 33-engine liftoff

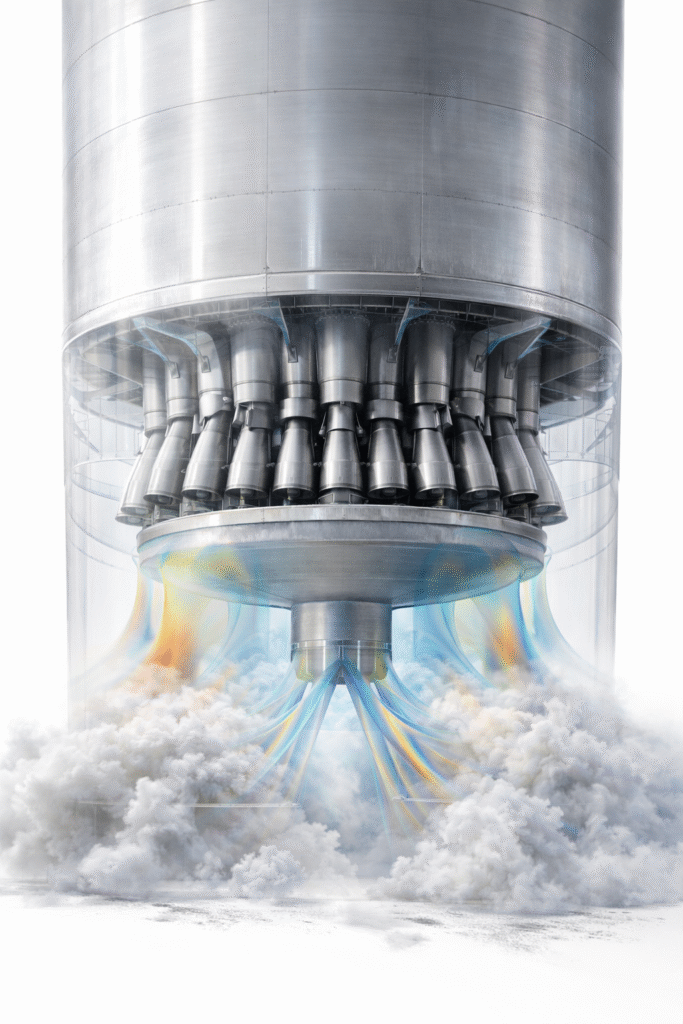

At liftoff, Super Heavy V3 produces nearly 75 meganewtons of thrust, equivalent to lifting more than 7,600 metric tons off the ground. But thrust is only half the story. Each Raptor engine generates intense pressure oscillations as liquid methane and oxygen burn at extreme chamber pressures. When 33 of them fire together, the result is a storm of acoustic loads exceeding 180 decibels near the engine section.

At that level, sound behaves less like noise and more like a physical удар—a hammering force capable of cracking welds, shaking avionics loose, and triggering destructive resonance inside the vehicle. Historically, this exact problem has destroyed rockets, from early Soviet launchers to Saturn V’s infamous pogo oscillations.

This is why Super Heavy V3 vibration control is not a secondary concern. It is mission-critical.

Why Super Heavy V3 faces unprecedented acoustic loads

No operational rocket has ever attempted to launch with this many high-thrust engines firing simultaneously. Even Falcon Heavy uses only 27 engines spread across three cores. Super Heavy concentrates all 33 engines beneath a single massive structure, amplifying interaction effects between exhaust plumes, shock waves, and reflected sound from the launch pad.

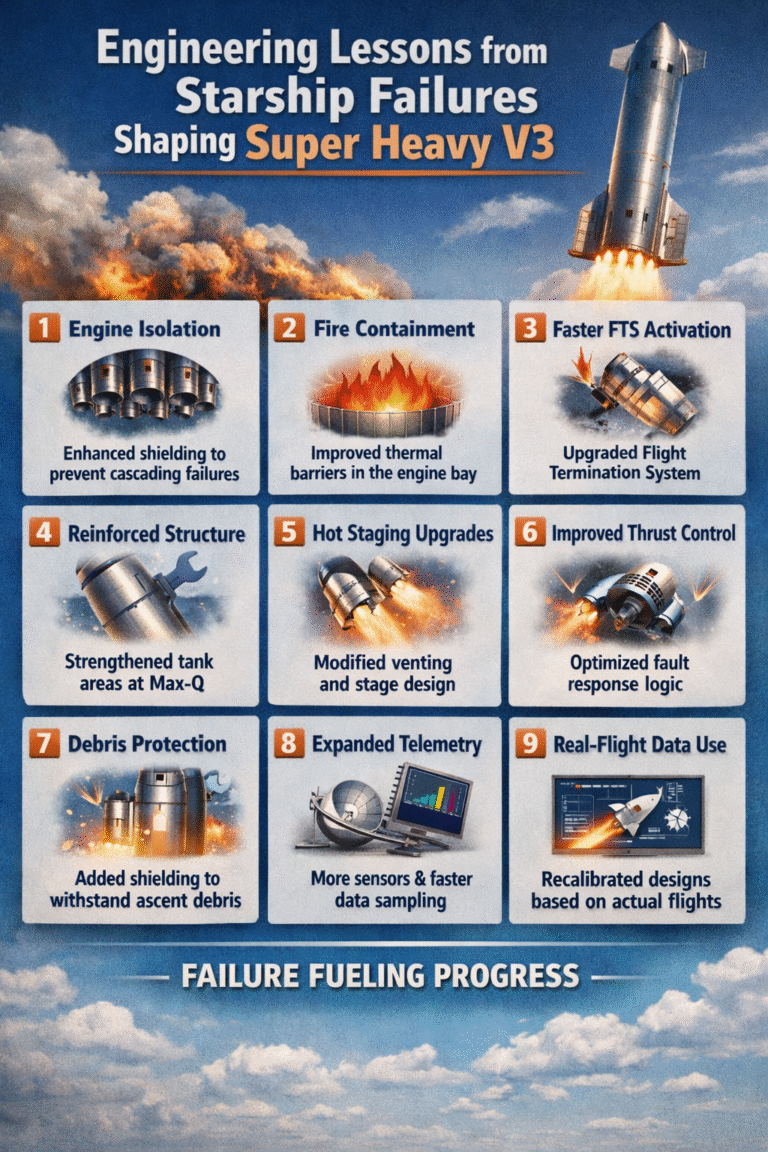

Earlier Starship test flights revealed just how destructive uncontrolled acoustics can be. The first integrated flight test in 2023 severely damaged the launch pad, sending debris flying and exposing how raw acoustic energy can propagate upward into the booster itself. That data directly shaped the V3 design.

Super Heavy V3 vibration control at the engine level

One of the most misunderstood aspects of vibration management is that SpaceX does not attempt to make all engines behave identically. In fact, slight differences are intentional.

Each Raptor engine has unique combustion dynamics and turbopump behavior. Rather than forcing perfect synchronization—which could amplify resonance—SpaceX allows tiny phase differences between engines. This prevents vibration peaks from stacking together into a single destructive frequency.

This principle is similar to avoiding soldiers marching in lockstep on a bridge. Controlled variation reduces structural stress instead of increasing it, making Super Heavy V3 vibration control fundamentally different from older rocket designs.

Structural design that absorbs shock instead of resisting it

Material choice plays a major role in how vibration energy is handled. Super Heavy V3 is built primarily from 300-series stainless steel, a material selected not just for strength, but for ductility. Unlike brittle composites, stainless steel can flex microscopically under load and return to shape without cracking.

The heart of this system is the thrust puck, the thick structural interface that transfers engine forces into the booster. Rather than acting as a rigid plate, it spreads loads gradually across the vehicle, preventing localized stress spikes during ignition.

This controlled flexibility allows the booster to absorb vibration rather than fight it—a subtle but powerful design philosophy.

The launch pad as part of vibration control

One of the most important upgrades affecting Super Heavy V3 does not fly at all. It stays on the ground.

SpaceX’s water-cooled steel flame deflector and high-flow water deluge system are now integral to vibration and acoustic suppression. At liftoff, massive volumes of water flood the area beneath the engines in seconds. Water absorbs sound energy extremely efficiently, converting acoustic pressure into heat and steam.

This system can reduce sound levels by 20 to 30 decibels, dramatically lowering the stress transmitted into the booster’s lower structure and fuel tanks. NASA has used similar systems for decades, as documented on nasa.gov, while SpaceX continues refining its approach at spacex.com.

Software and real-time vibration monitoring

Modern rockets do not rely on passive strength alone. Super Heavy V3 is covered with sensors measuring acceleration, strain, and pressure oscillations in real time. If vibrations exceed safe limits, onboard computers can respond instantly by adjusting engine thrust, altering startup timing, or shutting down a problematic engine before damage spreads.

This active response capability means Super Heavy V3 vibration control is not static. It adapts moment by moment during the most violent phase of flight.

Why this matters beyond SpaceX

Solving vibration and acoustic loads at this scale changes what is possible in spaceflight. Reliable heavy-lift rockets enable cheaper satellite launches, faster global internet coverage, improved Earth observation, and sustained missions to the Moon and Mars.

For everyday life, this translates into better communications, disaster monitoring, navigation, and scientific data—all made possible by launch systems that can survive their own power.

Final thoughts

Super Heavy V3 proves that raw thrust alone does not define progress. Intelligence does. Managing 33 engines firing together is not about overpowering physics, but about working with it. If this system performs as designed, it could redefine how future super-heavy rockets are built worldwide.

If this deep dive helped you understand the hidden science behind rocket launches, share it with fellow space enthusiasts and join the discussion below. Do you think Super Heavy V3 will finally unlock truly routine access to space?

Frequently Asked Questions

What is Super Heavy V3 vibration control?

It is the combination of engine phasing, structural damping, acoustic suppression, and real-time software monitoring that protects the booster during liftoff.

How loud is a Super Heavy launch?

Sound levels near the engines can exceed 180 decibels, making acoustic suppression essential.

Is Super Heavy V3 currently operational?

It is still in development, but its design is based on extensive flight and static-fire data.

Why not use carbon composites instead of steel?

Stainless steel offers better vibration absorption, heat tolerance, and fatigue resistance.

Can vibration really destroy a rocket?

Yes. Uncontrolled resonance has caused multiple historical launch failures.