Super Heavy V3 stainless steel structure sounds like a simple material choice, but it may be one of the most critical engineering decisions ever made in modern rocketry. Why would SpaceX deliberately move away from lightweight aluminum-lithium alloys—used for decades in rockets—and instead build the world’s most powerful booster out of stainless steel, a material many once considered too heavy for spaceflight? The answer lies in extreme temperatures, brutal physics, and SpaceX’s long-term goal of making rockets fly again and again like airplanes.

At Starbase in South Texas, Super Heavy V3 is being designed to endure temperature swings that would permanently weaken most traditional rocket materials. During fueling, liquid oxygen chills the structure to about –183°C, while during ascent and reentry, aerodynamic heating can push surface temperatures close to 800–1,000°C in certain regions. This is where the Super Heavy V3 stainless steel structure fundamentally changes the game.

Why Aluminum-Lithium Rockets Hit a Thermal Wall

For decades, aluminum-lithium alloys have been the gold standard in aerospace because of their excellent strength-to-weight ratio. Rockets like the Space Shuttle external tank and NASA’s SLS core stage rely heavily on these materials. However, aluminum-lithium has a major weakness: heat.

At temperatures above 150–200°C, aluminum alloys begin to lose a significant portion of their mechanical strength. Prolonged exposure can cause permanent deformation, micro-cracking, and fatigue damage. This is acceptable for rockets designed to fly once, but it becomes a serious problem for a vehicle meant to be reused dozens of times.

This limitation is exactly why the Super Heavy V3 stainless steel structure exists.

How Stainless Steel Thrives Where Aluminum Fails

Stainless steel retains much of its structural strength at temperatures where aluminum alloys rapidly weaken. Certain stainless steel grades used by SpaceX can maintain integrity well beyond 800°C, and in controlled conditions, even higher. This allows Super Heavy V3 to tolerate intense aerodynamic heating without relying on thick, heavy thermal protection systems across the entire booster.

Equally important is thermal cycling. The Super Heavy V3 stainless steel structure can repeatedly move from cryogenic cold to extreme heat without suffering the same level of fatigue damage seen in aluminum-lithium tanks. That durability is essential for rapid reuse.

SpaceX has stated that long-term reusability is not optional—it is the foundation of Starship’s economics.

Strength, Cost, and Manufacturing Speed

Another overlooked advantage of the Super Heavy V3 stainless steel structure is cost. Aerospace-grade aluminum-lithium alloys are expensive, often costing several times more per kilogram than stainless steel. Stainless steel is not only cheaper, but it is also easier to weld, repair, and modify during rapid prototyping.

This matters because SpaceX does not build rockets the traditional way. Instead of waiting years between design revisions, SpaceX iterates in months. Stainless steel enables faster manufacturing cycles, quicker repairs after testing, and easier structural upgrades between versions like V2 and V3.

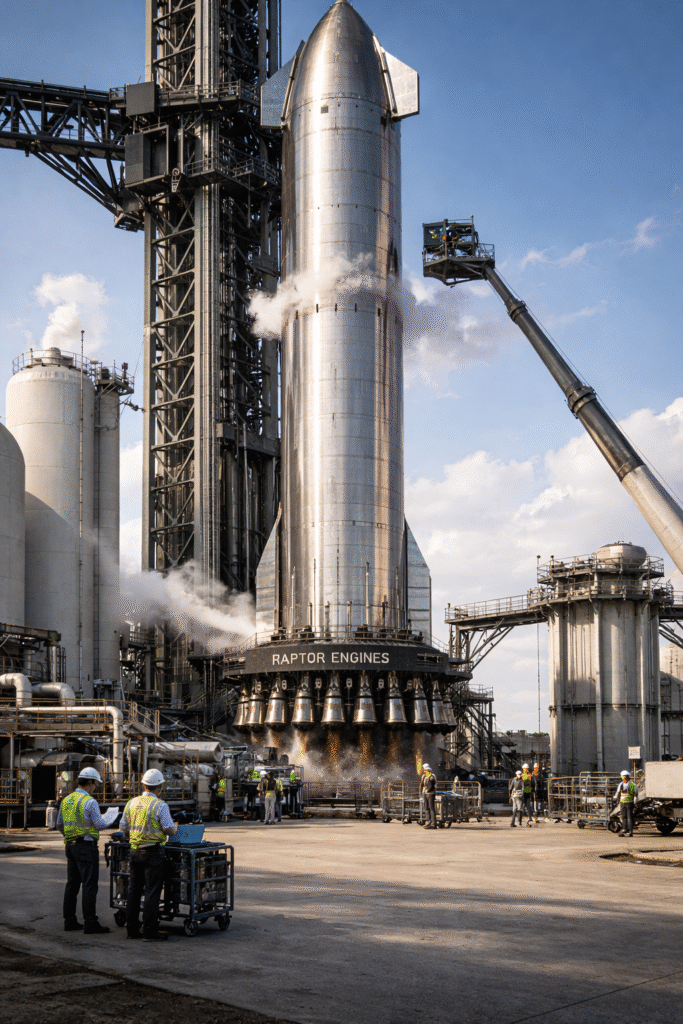

While stainless steel is heavier, Super Heavy compensates with raw power. The booster produces approximately 17 million pounds of thrust (about 75 meganewtons) using 33 Raptor engines, giving it enough performance margin to absorb the extra mass while still delivering massive payloads.

Thermal Resistance Meets Reusability

The Super Heavy V3 stainless steel structure directly supports SpaceX’s goal of flying boosters repeatedly with minimal refurbishment. Aluminum-based rockets often require extensive inspections after a single flight due to heat-related stress. Stainless steel dramatically reduces that burden.

This design philosophy mirrors what SpaceX achieved with Falcon 9, but at a far larger scale. If Super Heavy V3 can fly multiple times with only minor checks, launch costs could drop below $10 million per flight, compared to hundreds of millions for traditional heavy-lift rockets.

That cost reduction doesn’t just matter for SpaceX—it affects everyone.

How This Impacts Life on Earth

Cheaper, more durable launch vehicles unlock real-world benefits. Lower launch costs mean more satellites for global internet coverage, faster disaster monitoring during hurricanes and wildfires, and expanded space-based research in medicine, climate science, and materials engineering.

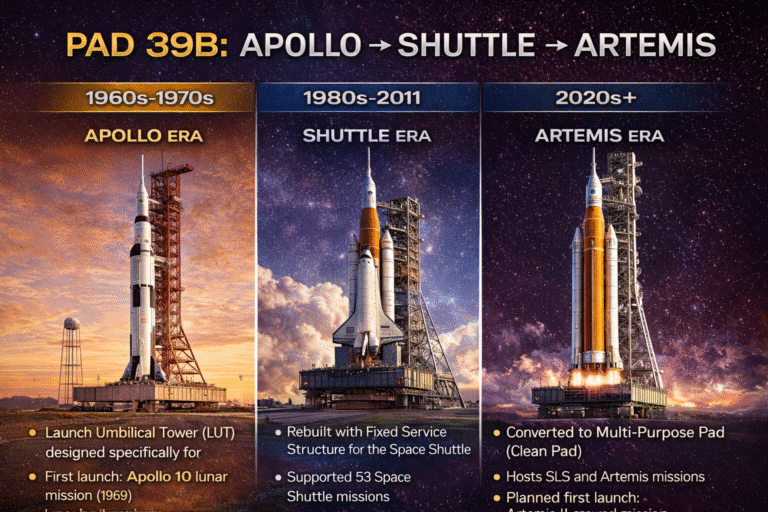

The Super Heavy V3 stainless steel structure also supports NASA’s Artemis program, where Starship has been selected as the Human Landing System. A rocket that can withstand extreme thermal stress and fly repeatedly increases mission reliability and reduces taxpayer cost.

You can explore SpaceX’s official Starship architecture on the SpaceX Starship page, and NASA’s lunar plans on the NASA Artemis program site, both of which underline why durability and thermal resistance are now mission-critical.

A Design Choice That Rewrites Rocket Engineering

What makes this story remarkable is that stainless steel was once considered outdated for rockets. SpaceX turned that assumption upside down. By prioritizing thermal resistance, durability, and manufacturability over pure weight savings, the Super Heavy V3 stainless steel structure reflects a shift from disposable rockets to sustainable spaceflight systems.

In hindsight, this choice may be remembered as one of the defining engineering decisions that made large-scale space access possible.

Final Thoughts: Why This Matters More Than It Seems

This is not just about metal. It’s about redefining how humanity builds machines to leave Earth. The Super Heavy V3 stainless steel structure proves that sometimes progress comes from rethinking old ideas with modern goals.

As Starship moves closer to operational flights, this design decision could be the quiet reason behind its success.

👉 Do you think stainless steel is the future of reusable rockets, or will newer materials eventually replace it? Share your thoughts and join the discussion.

❓ Frequently Asked Questions (FAQs)

Q1. Why did SpaceX choose stainless steel for Super Heavy V3?

Stainless steel offers superior thermal resistance, durability, lower cost, and better reusability compared to aluminum-lithium alloys.

Q2. How hot can the Super Heavy V3 stainless steel structure get?

It can tolerate temperatures approaching 800–1,000°C in certain flight conditions.

Q3. Isn’t stainless steel heavier than aluminum?

Yes, but Super Heavy compensates with extreme thrust—about 17 million pounds—making the mass penalty manageable.

Q4. Does stainless steel help reduce launch costs?

Yes. It lowers material costs, simplifies manufacturing, and reduces refurbishment needs between flights.

Q5. Will other rockets adopt stainless steel designs?

If Starship proves successful, stainless steel or similar high-temperature alloys could influence future heavy-lift rocket designs.