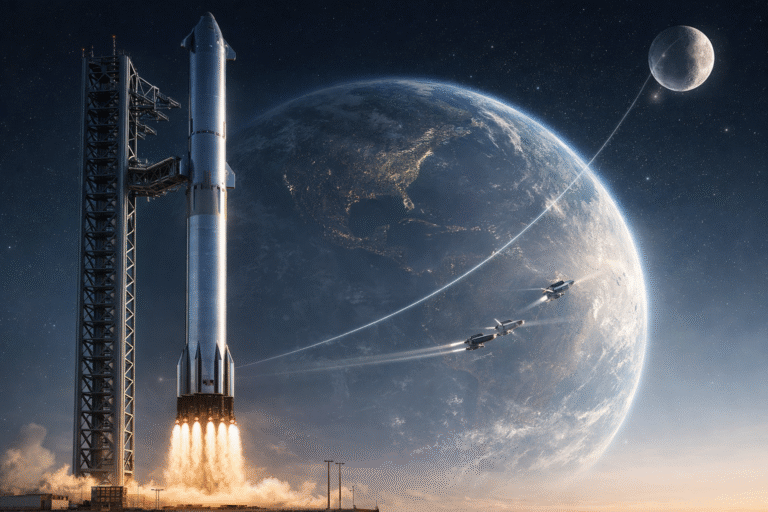

Falcon 9 Reusability Explained: How Flying One Booster 20 Times Saves Massive Manufacturing Energy

What if a single rocket could replace 20 brand-new ones—and save enormous amounts of energy in the process?

This is not science fiction. It’s already happening at SpaceX.

When Falcon 9 flies 20 times with the same booster, the implications go far beyond lower launch costs. It represents a revolution in manufacturing energy savings, sustainability, and the future of spaceflight. In this article, we explore how much manufacturing energy is saved, why it matters, and how reusable rockets are quietly changing life on Earth.

🚀 The Big Question: Why Does Reusability Matter So Much?

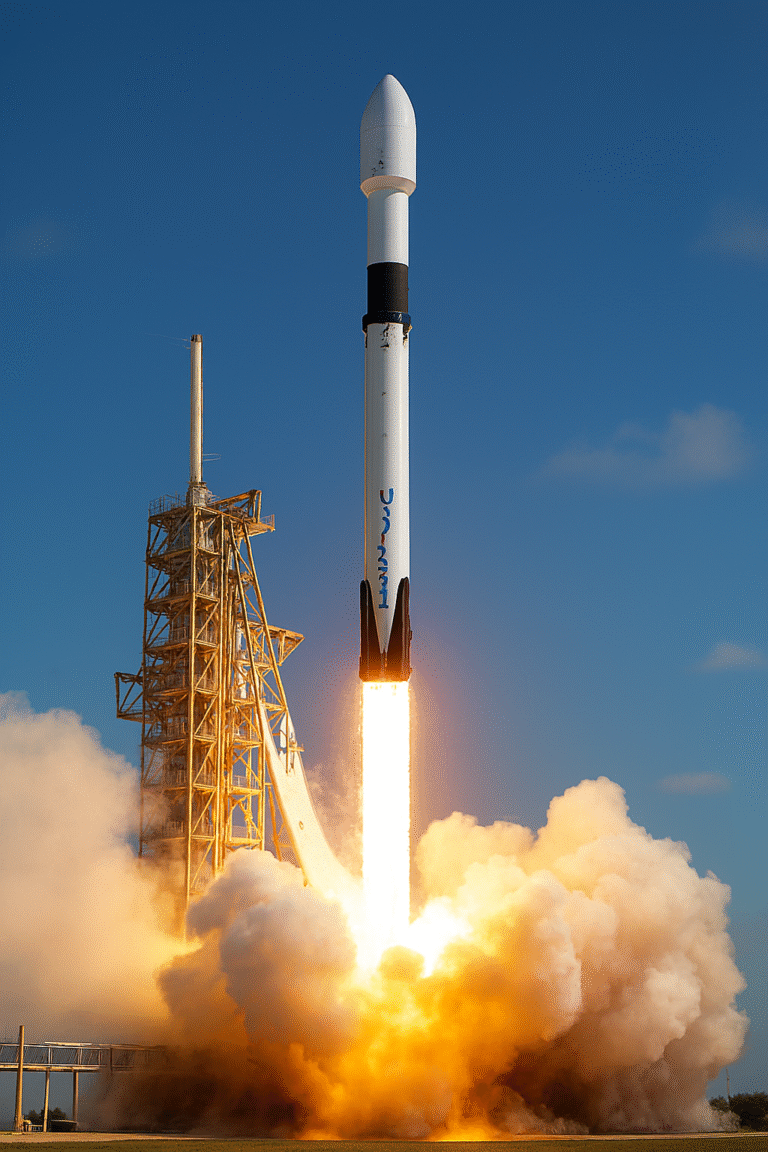

Traditionally, rockets were single-use machines. After one launch, most of the rocket was discarded into the ocean or burned up in the atmosphere. This meant that every mission required building an entirely new rocket from scratch—an energy-intensive and expensive process.

SpaceX flipped this model.

Instead of throwing away boosters, Falcon 9 lands, is refurbished, and flies again—sometimes within weeks. Today, several Falcon 9 boosters have already flown 15+ times, and SpaceX is pushing toward 20 flights per booster as a standard.

But how much energy does this actually save?

🔧 How Much Energy Does It Take to Build One Falcon 9 Booster?

Manufacturing a Falcon 9 first-stage booster involves:

- Mining and refining aluminum-lithium alloys

- Producing carbon composites

- Manufacturing 9 Merlin engines

- Precision machining, welding, and quality testing

- Cryogenic and structural testing

According to aerospace manufacturing estimates, building one medium-lift orbital-class rocket booster consumes roughly 1–1.5 terajoules (TJ) of energy.

🔍 1 terajoule is enough energy to power around 27,000 average homes for a day.

📊 Energy Comparison: 20 New Rockets vs 1 Reused Booster

Let’s break it down numerically:

Scenario 1: Traditional Rockets (No Reuse)

- 20 launches = 20 brand-new boosters

- Energy required:

20 × 1.2 TJ = ~24 terajoules

Scenario 2: Falcon 9 Reusability

- 1 booster reused 20 times

- Manufacturing energy: ~1.2 TJ

- Refurbishment energy (estimated): ~5–10% per flight

Total refurbishment energy over 19 re-flights:

≈ 1.5–2 TJ

✅ Total Energy Used: ~3–3.5 TJ

⚡ Final Result: Energy Saved

Energy saved by reusability:

24 TJ – 3.5 TJ = ~20.5 terajoules saved

That’s an 85–90% reduction in manufacturing energy.

To put this into perspective:

- ⚡ Enough energy to power over 500,000 homes for a day

- 🌍 Massive reduction in industrial emissions

- 🏭 Less strain on global manufacturing supply chains

🌱 Why This Matters Beyond SpaceX

This isn’t just about rockets or Mars missions.

Real-World Impacts:

- Lower launch costs → cheaper satellites → better internet (Starlink)

- Reduced industrial energy use → lower carbon footprint

- Faster launch cadence → improved disaster monitoring & GPS services

- New sustainability model for aviation, shipping, and manufacturing

Reusable rockets prove that high-tech innovation and environmental responsibility can coexist.

🛰️ Falcon 9 vs Traditional Space Industry

Before SpaceX:

- One rocket = one mission

- High cost per kg to orbit

- Massive energy waste

After SpaceX:

- One booster = up to 20 missions

- Cost per kg reduced by up to 70%

- Energy efficiency never seen before in aerospace

You can explore more about reusable rockets on the official SpaceX website and technical insights from NASA.

🔥 Final Thoughts: A Quiet Revolution in Energy Efficiency

Flying a Falcon 9 booster 20 times isn’t just a milestone—it’s a statement. It shows that humanity can reach space without wasting Earth’s resources.

Reusable rockets are no longer an experiment. They are the new industrial standard.