How does the Raptor engine's design improve efficiency and cost-effectiveness for space exploration? ??

👋 Hey there, fellow space enthusiasts! Today, we’re diving into the fascinating world of rocket engine technology, specifically focusing on SpaceX's Raptor engine. This powerhouse is not just a marvel of engineering; it’s a game changer for the efficiency and cost-effectiveness of space exploration. Buckle up as we explore how the Raptor engine is reshaping our journey to the stars! 🚀

The Raptor engine has been designed with a focus on using methane and liquid oxygen (LOX) as propellants. This choice is significant for two main reasons: efficiency and sustainability. Traditionally, rocket engines have relied heavily on kerosene, but methane offers a higher specific impulse, which is a measure of efficiency. The Raptor boasts an impressive 330 seconds of specific impulse, considerably higher than traditional rockets like the Falcon 9, which sits at around 311 seconds! Higher efficiency means more payload capacity—allowing more scientists, equipment, and even tourists to explore beyond Earth. 🌌

Additionally, the use of methane aligns with SpaceX's vision for future Mars missions. Methane can potentially be produced on Mars through a process known as in-situ resource utilization (ISRU), which means that SpaceX could refuel its rockets on the surface of Mars, reducing the need to launch fuel from Earth. This strategy not only enhances mission sustainability but significantly cuts costs related to transporting fuel halfway across the solar system. 🌍✨

Now let's talk about how the engine's design contributes to its cost-effectiveness. The Raptor features a highly reusable architecture that allows for rapid refurbishment between flights. Compared to conventional rocket engines, the Raptor is designed for up to 100 flights with only minimal refurbishment, which can lower operational costs substantially. For comparison, the Falcon 9's Merlin engine, while also reusable, typically requires more extensive checks after each flight. 🔄

Moreover, the Raptor engine utilizes a revolutionary staged combustion cycle. This advanced system allows for complete combustion of fuel, leading to more efficient thrust and less wasted energy. In fact, SpaceX claims that the Raptor engine achieves roughly 230 metric tons of thrust—a supremely powerful output that propels Starship missions while still being more efficient than its predecessors. This design not only maximizes performance but also minimizes waste, both of which contribute to lower costs. 💸

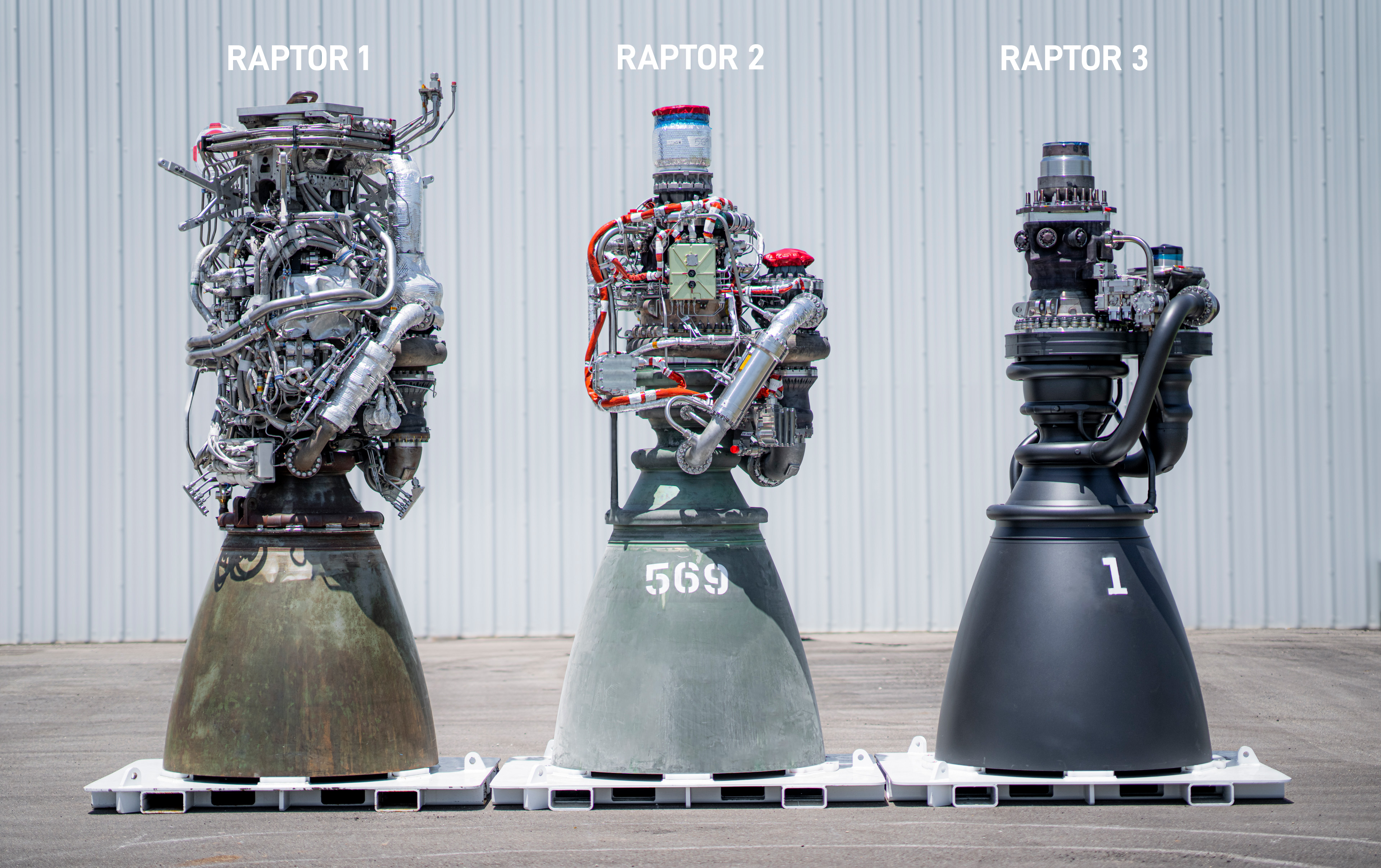

One additional aspect worth noting is the streamlined manufacturing process used for the Raptor engines. SpaceX employs advanced techniques like 3D printing to create many of the engine components. This innovation reduces production time and costs, making it feasible to ramp up production rapidly in response to future demands. Currently, SpaceX plans to produce over 1,000 Raptor engines for upcoming Starship missions, showcasing the company's commitment to efficiency at scale. 🔧

In conclusion, the Raptor engine's clever design not only enhances performance but also embodies the ethos of sustainable and cost-effective space exploration. With its innovative use of methane, robust reusability, and advanced manufacturing techniques, the Raptor is set to transform how we venture beyond our planet.

So, keep your eyes on the stars, because the future of space travel is brighter than ever! #SpaceX #RaptorEngine #RocketScience #CostEffectiveSpaceTravel #SustainableExploration

image credit: SpaceX