Why does the Raptor engine use a full-flow staged combustion cycle?

The Raptor engine, developed by SpaceX, represents a significant advancement in rocket engine technology. It is designed to power Starship, the next-generation spacecraft intended for interplanetary travel, with the ultimate goal of enabling human missions to Mars and beyond. The Raptor engine stands out from other rocket engines due to its unique design and impressive performance characteristics. It utilizes a full-flow staged combustion cycle, a sophisticated and demanding approach that offers significant advantages in terms of efficiency, thrust, and overall performance.

The development of the Raptor engine has been an ongoing process, with several iterations and improvements made over the years. SpaceX is known for its iterative approach to engineering, constantly refining and optimizing its designs based on testing and real-world data. The current iteration of the Raptor engine is designed to operate on liquid methane (CH4) and liquid oxygen (LOX), a propellant combination considered to be highly promising for deep-space missions. Methane is readily available on Mars, and its use as a propellant could potentially enable the in-situ production of fuel on the Martian surface. The engine's core is designed to be re-used. This design choice directly aligns with SpaceX's broader strategy of developing fully reusable launch systems to dramatically reduce the cost of space travel.

The full-flow staged combustion cycle is a complex engine architecture. It offers several key advantages over other engine cycles. In a full-flow staged combustion engine, all of the propellant, both fuel and oxidizer, is used to power the turbines that drive the engine's pumps. This is in contrast to other engine cycles, such as the gas generator cycle, where a portion of the propellant is used to generate gas to power the turbines, and then it is exhausted overboard. In the case of Raptor, both the liquid methane and liquid oxygen are passed through separate preburners. These preburners use a small portion of the propellant to drive the turbines. One preburner uses fuel-rich combustion. The other uses oxidizer-rich combustion. The hot gases generated in the preburners then power the turbines. The preburners generate hot gases at a controlled ratio to drive the turbopumps. This system ensures that all of the propellants are completely combusted in the main combustion chamber.

The Raptor engine employs two separate preburners. One preburner is fuel-rich, meaning it uses an excess of liquid methane. The other preburner is oxidizer-rich, meaning it uses an excess of liquid oxygen. The fuel-rich preburner combusts a portion of the methane with oxygen. The oxidizer-rich preburner combusts a portion of the oxygen with methane. This process yields hot gases that drive the turbines. These turbines, in turn, power the pumps. The pumps feed the propellants into the main combustion chamber. The hot gases from both preburners are then injected into the main combustion chamber, where they undergo complete combustion, producing the high-pressure, high-temperature exhaust gases that generate thrust. This complex process ensures the maximum efficiency and high thrust. The design must handle the complexities of handling both cryogenic fuel and oxidizer.

This cycle offers several key advantages. First, it maximizes combustion efficiency. By ensuring that all of the propellant is completely combusted, the engine can extract the maximum amount of energy from the fuel. This leads to a higher specific impulse, a measure of the engine's fuel efficiency. The Raptor engine is designed to achieve a high specific impulse, which is crucial for interplanetary missions, where fuel efficiency is a primary concern. The engine has a target vacuum specific impulse (Isp) of approximately 380 seconds. This represents a significant improvement over the specific impulse of other rocket engines.

Second, the full-flow staged combustion cycle allows for extremely high chamber pressures. The Raptor engine is designed to operate at a chamber pressure of 300 bar (4,350 psi). This is a very high pressure compared to other rocket engines. Higher chamber pressure translates directly into higher thrust and a better thrust-to-weight ratio. This is a critical advantage for Starship, which needs to generate a tremendous amount of thrust to lift off from Earth and eventually, from other planetary bodies with lower gravity.

Third, the cycle reduces the risk of coking, a process where carbon deposits can form within the engine. These deposits can reduce engine performance and even lead to engine failure. By carefully controlling the combustion process and ensuring that all of the propellant is completely combusted, the full-flow staged combustion cycle minimizes the potential for coking. This contributes to the engine's reliability and durability. This design choice means the engine can be reused. SpaceX aims to fully reuse the engine.

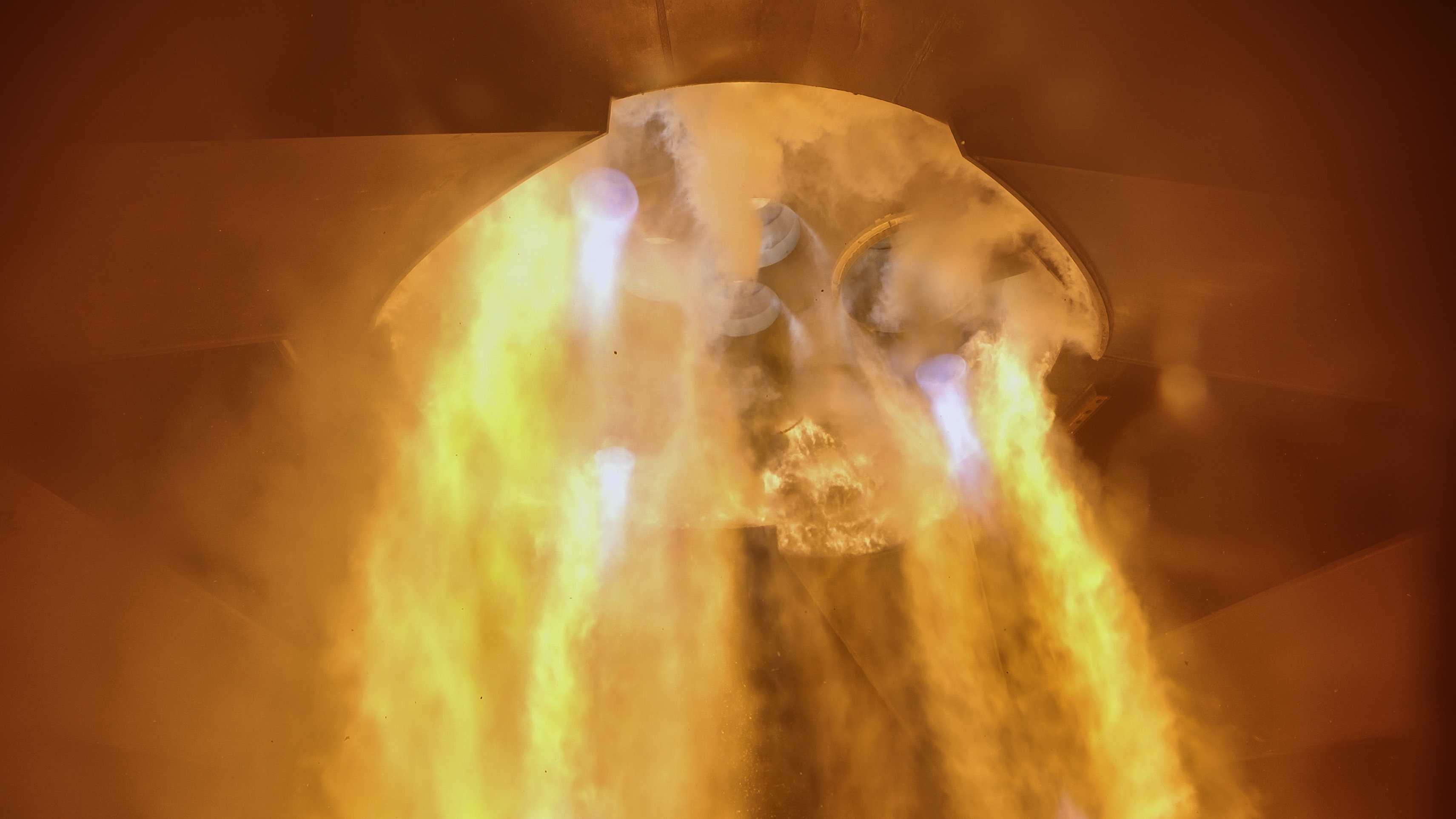

The Raptor engine is a sophisticated piece of engineering. The engine is designed to generate a significant amount of thrust. The specific number is dependent on the variant. The sea-level thrust of a single Raptor engine is approximately 2,300 kilonewtons (517,000 pounds-force). The vacuum thrust can be even higher. The engines will be clustered together to provide the overall thrust needed for the mission. Starship's Super Heavy booster will have as many as 33 Raptor engines.

The full-flow staged combustion cycle is a significant factor in the Raptor engine's superior performance. The full flow staged combustion cycle allows for a very high thrust-to-weight ratio and very high efficiency. The Raptor engine is intended to be a cornerstone of the future of space travel.

Why does the Raptor engine use a full-flow staged combustion cycle?

The Raptor engine uses a full-flow staged combustion cycle to maximize combustion efficiency, achieve extremely high chamber pressures, reduce the risk of coking, and ultimately achieve a high specific impulse and thrust-to-weight ratio, all of which are crucial for the performance requirements of Starship and its mission to deep space.

Humanize