How SpaceX Uses CAD to Design and Build Rockets

SpaceX is a private American aerospace manufacturer and space transport services company founded by Elon Musk in 2002. The company is known for its reusable rockets, which have made it possible to launch satellites and spacecraft more cheaply than ever before.

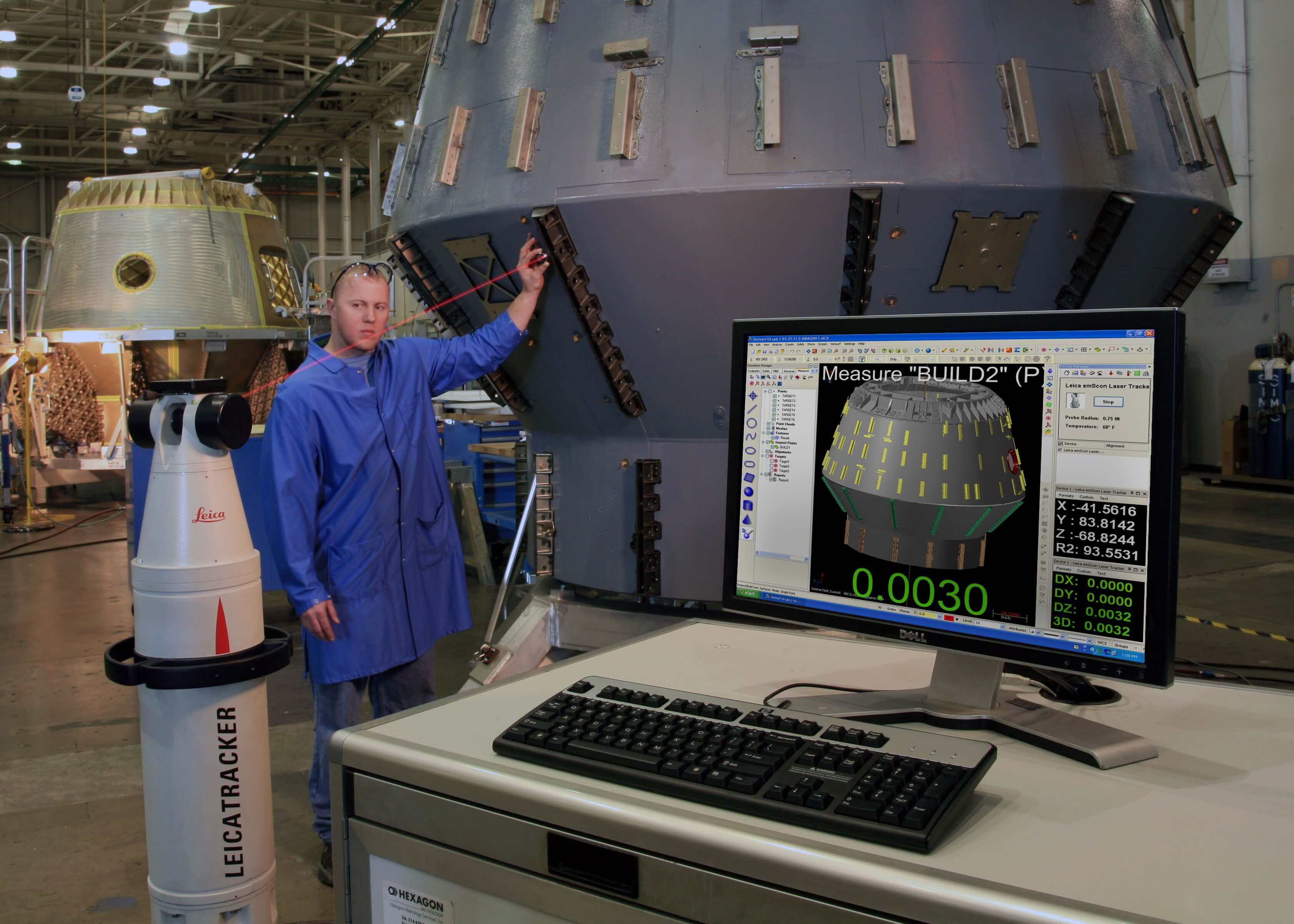

One of the key technologies that SpaceX uses to design and build its rockets is computer-aided design (CAD). CAD software allows engineers to create detailed 3D models of rockets and other aerospace components. These models can then be used to simulate the performance of the rockets, identify potential problems, and optimize the design.

SpaceX uses a variety of CAD software, including Siemens NX and CATIA. These software packages offer a wide range of features that are essential for aerospace engineering, such as:

- 3D modeling

- Finite element analysis (FEA)

- Fluid dynamics analysis

- Manufacturing simulation

- Data management

CAD software has played a critical role in the development of SpaceX's rockets. For example, the Falcon 9 rocket was designed using CAD software, and the company used CAD software to simulate the performance of the rocket during its early development. This allowed SpaceX to identify and fix potential problems before the rocket was ever launched.

CAD software is also used by SpaceX to manufacture its rockets. The company uses CAD data to create machined parts, molds, and tooling. This ensures that the rockets are manufactured to the highest standards of accuracy and precision.

CAD software is a valuable tool for SpaceX, and it has helped the company to design and build some of the most advanced rockets in the world. As SpaceX continues to push the boundaries of space exploration, CAD software will continue to play an essential role in the company's success.

Benefits of Using CAD for Aerospace Engineering

There are many benefits to using CAD for aerospace engineering. Some of the most important benefits include:

- Improved design: CAD software allows engineers to create detailed 3D models of aerospace components. This allows engineers to visualize the design and identify potential problems.

- Reduced risk: CAD software can be used to simulate the performance of aerospace components. This allows engineers to test the design and identify potential risks before the component is ever built.

- Increased efficiency: CAD software can automate many of the tasks involved in aerospace engineering. This can free up engineers to focus on more creative and strategic work.

- Improved communication: CAD models can be shared with other engineers and stakeholders. This allows everyone to see the design and collaborate on it.

The Future of CAD in Space Exploration

CAD software is playing an increasingly important role in space exploration. As the technology continues to develop, CAD will become even more powerful and sophisticated. This will allow engineers to design and build even more advanced spacecraft.

In the future, CAD software could be used to design and build spacecraft that are capable of traveling to Mars and beyond. CAD could also be used to design new types of propulsion systems and life support systems.

The possibilities are endless, and CAD is sure to play a major role in the future of space exploration.