200th improved Raptor engine is shipped by SpaceX in Starship.

A day after revealing the completion of the 200th Falcon upper stage and Merlin Vacuum engine, the company announced that it also recently finished building the 200th upgraded Raptor engine. The established success and reliability of the Falcon upper stage and MVac is likely years away from being scratched by Starship and Raptor. Raptor is more complex, more efficient, more powerful, and younger than MVac. The first version of the engine is called Raptor 2. Between the start of full-scale testing in February of last year and July of this year, it manufactured 100 Raptor 1 engines.

Advertisement

Advertisement

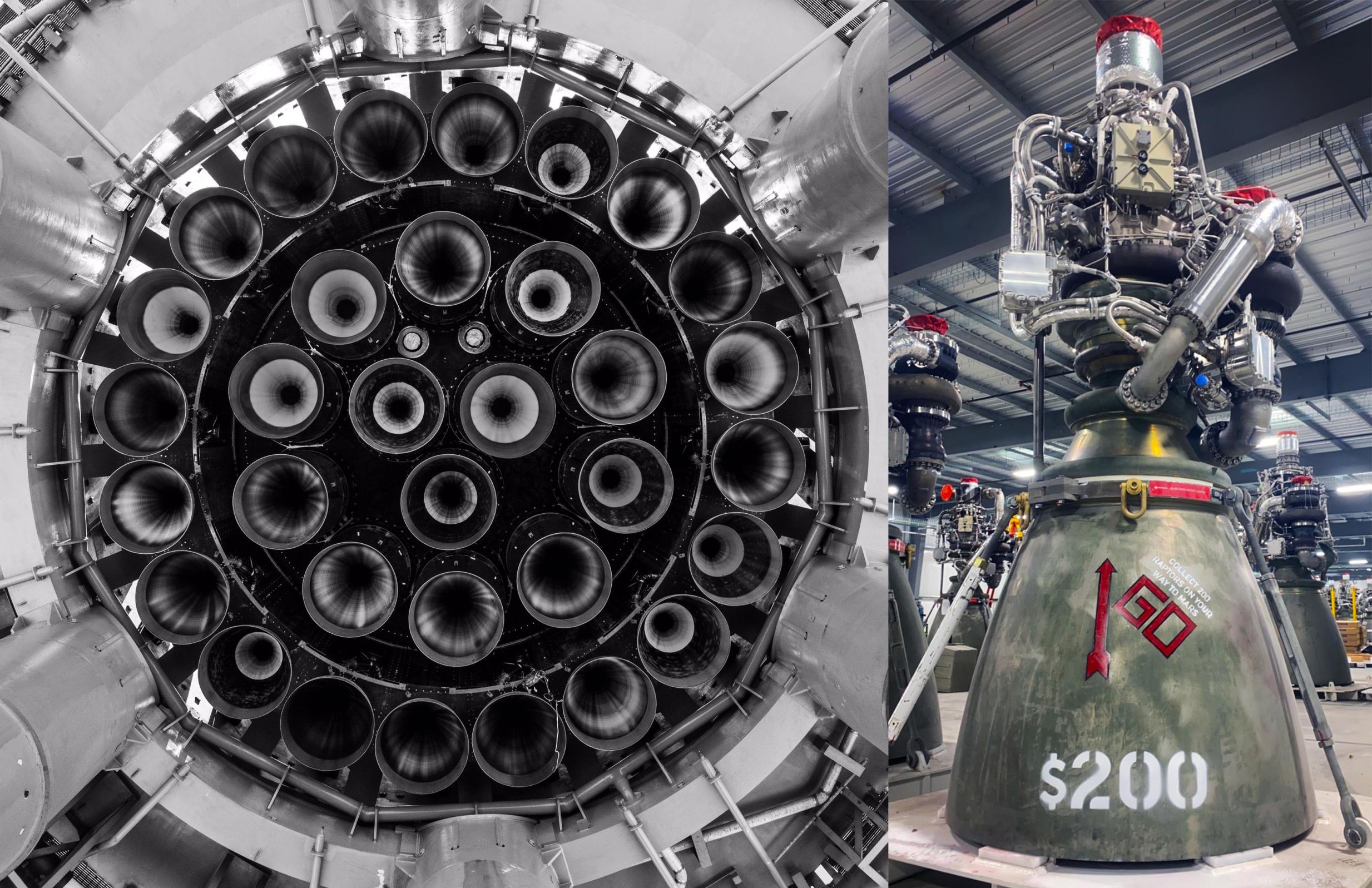

When Raptor 2 took over, the total number of engines produced was likely to be between 125 and 150, but pales in comparison to the ambitions of the company. The purpose of Raptors 2 was to make future Raptors easier, faster, and cheaper to manufacture. The goal is to eventually reduce the cost of production to $1000 per ton of thrust, or $230,000 at the current target of 230 tons. According to Musk, each early Raptor 1 prototype cost more than $2 million for 185 tons of thrust. It is not clear if that ever changed.

Advertisement

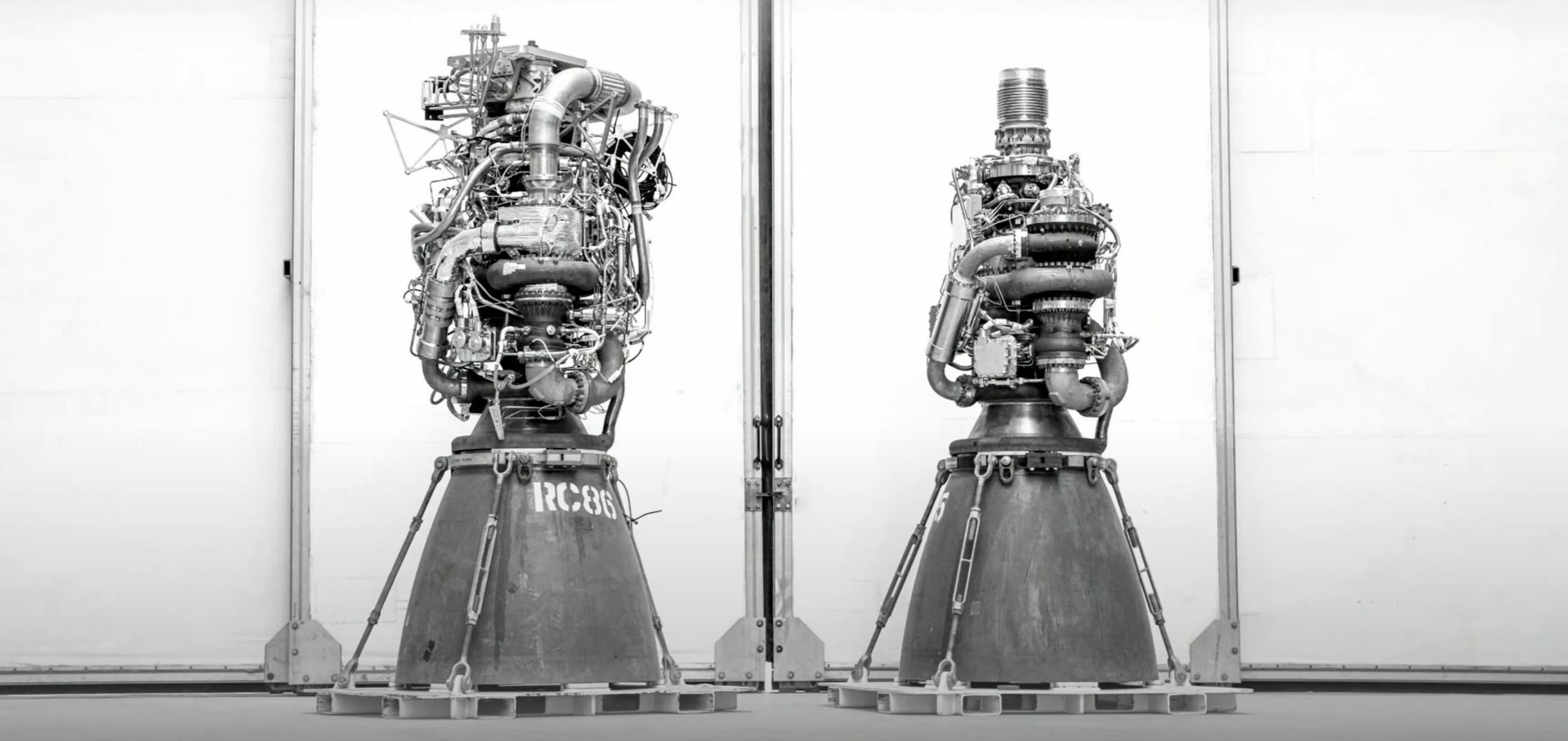

A large part of the maze of primary, secondary, and tertiary plumbing was removed by SpaceX. The torch igniter system was removed from the main combustion chamber. The simplification made it much easier to build a theory, and the production figures confirm that theory. It was possible to boost Raptor 2's thrust by 25% by sacrificing 1% of Raptor 1's efficiency, despite the simplifications. The last one of the Raptors. It was one of the first Raptors. (SpaceX)

Advertisement

Advertisement

Beginning with its first delivery in February 2018, SpaceX produced the first 100 Raptor 1 engines in about 36 months

In the first 11 to 12 months of production, the company has delivered 200 engines. That equates to at least six times the average throughput. Musk stated in June that he was aiming the engine every 12 hours by the end of the year. It took far longer than usual for that progress to be realized. In October 2022, a senior NASA Artemis Program official revealed that the company had achieved sustained production of one Raptor 2 engine per day for a full week. It is necessary for a high rate to make Raptor one of the fastest-produced orbital-class rocket engines in history.

Advertisement

The upper stage of the Starship requires three sea-level-optimized Raptors and three vacuum-optimized Raptors, with plans to increase that to nine engines total. The Super Heavy booster is powered by Raptors. Two ships show off a single set of Raptors. (SpaceX)

Orbital-class versions of Starship and Super Heavy have never flown, let alone demonstrated successful recovery or reuse, so SpaceX has to operate under the assumption that every orbital test flight will consume 39 Raptors

Even after the reuse of Super Heavy boosters becomes viable, taking significant strain off of Raptor demand, SpaceX wants to manufacture a fleet of hundreds or even thousands of Starships and a similarly massive number of boosters. To outfit that massive fleet, SpaceX would have to mass-produce orbital-class Raptor engines at a scale that has never been attempted. It will likely be years before SpaceX is in a position to attempt to create that mega-fleet.

Advertisement

The production rate of one engine per day is good enough to support the next few years of realistic engine demand if the Raptor 2 engines are already built. There is a chance that the first orbital Starship launch attempt could happen as early as December 2022. The company currently has permission for up to five orbital launches per year out of its Starbase, Texas facilities and will likely try to take full advantage of that with several back-to-back test flights in a period of 3-6 months.

Advertisement