Why Tesla Samsung and Panasonic are adopting cobalt-free batteries

How new cobalt-free lithium-ion battery reduces costs without sacrificing performance

Thursday, November 18, 2021 | Chimniii Desk

Key Highlights

- For the last four years, the average price of cobalt has been greater than the average price of all other battery metals combined.

- Cobalt supply for US businesses is in jeopardy as a result of the US-China trade dispute.

- Tesla already employs LFP batteries in its China-manufactured Model 3 and Model Y automobiles.

- Among its objectives is the elimination of cobalt from lithium batteries by 2030.

Advertisement

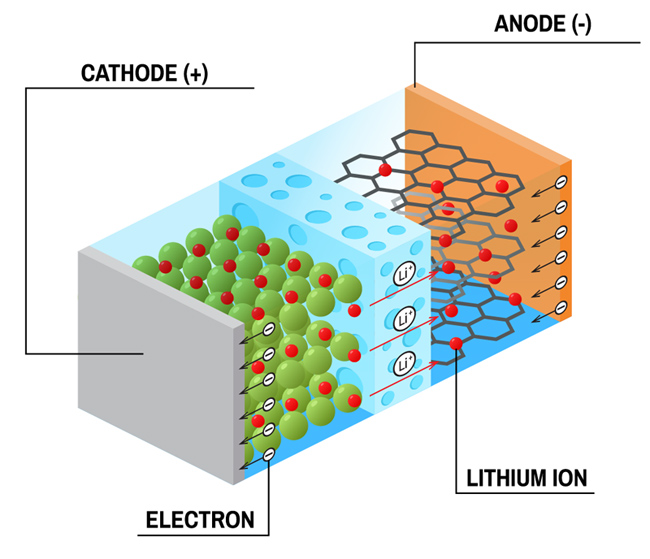

Lithium-ion batteries are composed of a variety of components, including lithium, nickel, aluminium, iron, manganese, and cobalt. Cobalt is the most expensive of these metals. For the last four years, the average price of cobalt has been greater than the average price of all other battery metals combined.

"For mass electrification to occur, there are numerous sentiments that cobalt should be abolished or reduced to the bare minimum," says Chibueze Amanchukwu, a University of Chicago professor of molecular engineering.

Cobalt's price has also historically been somewhat variable. A portion of this volatility is due to the fact that cobalt is typically mined as a byproduct of nickel and copper mining, and hence is subject to the same demand and price changes as other metals. Cobalt mining and refinement are similarly geographically restricted.

"The majority of the world's battery-grade cobalt reserves are situated in the Democratic Republic of Congo, where cobalt mining is associated with human rights violations and child labour," according to Sam Adham, a senior powertrain research analyst at LMC Automotive.

Chinese investors own over 70% of Congo's mining sector. China also controls more than 80% of the cobalt refining industry, which converts the raw material into commercial-grade cobalt metal suitable for use in electric vehicles. Cobalt supply for US businesses is in jeopardy as a result of the US-China trade dispute.

Advertisement

There are currently some cobalt-free batteries available, but they come with certain trade-offs.

"A practical cobalt-free battery is currently available, and it is called lithium iron phosphate, or LFP. However, the primary disadvantage of LFP is its low energy density and thus limited driving range," Adham explains.

LFP batteries have improved, prompting more automakers to adopt the technology, which is significantly less expensive than cobalt-based batteries. Tesla already employs LFP batteries in its China-manufactured Model 3 and Model Y automobiles.

Additionally, Tesla announced that it will now use LFP batteries in all of its entry-level Model 3 and Model Y vehicles. Additionally, Ford and Volkswagen have stated that they will offer automobiles equipped with LFP batteries.

Advertisement

As with cobalt, Chinese businesses such as BYD and Contemporary Amperex Technology Limited, or CATL, dominate the supply chain for lithium iron phosphate, or LFP, batteries. To help guide investment in developing local lithium battery manufacturing and supporting future R&D, the US Department of Energy developed a national roadmap in June.

Among its objectives is the elimination of cobalt from lithium batteries by 2030. Two start-ups located in the United States, Sparkz and Texpower, claim to be able to assist, albeit the companies have yet to demonstrate their technologies in electric vehicles.

Watch the video to learn more about how companies are reducing the industry's reliance on cobalt-containing batteries and how eliminating cobalt can help make EVs more affordable.

Following the release of this film, CEO Evan Erickson stated that TexPower is now building a facility capable of producing hundreds of tonnes of material per year. He claimed he made an error during the taped interview.

How new cobalt-free lithium-ion battery reduces costs without sacrificing performance

The University of Texas at Austin has demonstrated the development of a cobalt-free, high-energy lithium-ion battery.

Advertisement

Cobalt ore, mined from the Congo. Credit: RHJPhtotoandilustration

For decades, researchers have sought to exclude cobalt from high-energy batteries that power electronic devices, owing to the material's high cost and human rights implications associated with its mining. However, previous attempts have fallen short of the performance benchmarks set by cobalt batteries.

However, the Cockrell School of Engineering at the University of Texas at Austin (UTA) announced a possibly game-changing development this month.

A group of academics believes they have unlocked the code to a cobalt-free, high-energy lithium-ion battery, obviating the need for cobalt and paving the path for cost savings in battery manufacturing while improving performance in some respects.

A critical component of this advancement is a new class of cathodes (the electrode in a battery that normally contains cobalt), which are anchored by a high nickel content. The cathode in their study is composed of 89 percent nickel, with the other elements being manganese and aluminium.

A battery with a higher nickel content can store more energy. This enhanced energy density could result in a phone's battery life being extended or an electric vehicle's range being boosted with each charge.

Advertisement

Increased energy density typically comes with a cost, such as decreased cycle life – the number of times a battery can be charged and drained before losing efficiency and becoming unchargeable.

Eliminating cobalt typically lowers a battery's kinetic reaction, resulting in decreased rate capability - the rate at which the cathode can be charged or discharged.

The researchers assert, however, that they overcame the short cycle life and low rate capability issues by selecting the best metal combination and maintaining an even dispersion of their ions.

The majority of lithium-ion battery cathodes are composed of metal ion combinations, such as nickel-manganese-cobalt (NMC) or nickel-cobalt-aluminum (NCA) (NCA).

Cathodes can account for about half of the total material cost of the battery, with cobalt being the most expensive element. At around $28,500 per tonne, it is more expensive than nickel, manganese, and aluminium combined, and it accounts for between 10% and 30% of the majority of lithium-ion battery cathodes.

"Cobalt is the least abundant and most expensive component in battery cathodes," explains Arumugam Manthiram, a professor at UTA's Walker Department of Mechanical Engineering and the Texas Materials Institute. "And we are eradicating it entirely."

The researchers broke new ground by operating at the atomic level. They were able to ensure that the ions of the various metals were equally distributed throughout the crystal structure of the cathode during synthesis.

When these ions aggregate, performance diminishes, a problem that previously hampered cobalt-free, high-energy batteries. The researchers avoided performance degradation by maintaining a uniform distribution of the ions.

Advertisement

"Our goal is to replace cobalt with readily available and affordable metals while maintaining performance and safety," said Wangda Li, a PhD graduate, "and to use industrial synthesis procedures that are immediately scalable."

The team has now founded a company named TexPower to commercialise the concept. The researchers were funded by the US Department of Energy, which hoped to reduce reliance on imports for critical battery ingredients.

In recent years, industry has embraced the cobalt-free movement, most notably Tesla, which is striving to eradicate the metal from the batteries that power its electric vehicles. With huge government organisations and business firms concentrating their efforts on lowering their reliance on cobalt, it's predictable that this quest has become competitive.

The team at UTA has overcome the obstacles that have stymied earlier attempts by selecting the optimal combination of materials and controlling their distribution precisely. This achievement may contribute to satisfying the exponentially expanding demand for batteries, which are expected to become a critical technology in the 2020s and 2030s.

"We're boosting energy density and cutting costs while maintaining cycle life," Professor Manthiram adds. "This translates into increased driving range for electric vehicles and improved battery life for computers and smartphones."

Advertisement