Rivian is one of the few pure electric vehicle manufacturers that has outsourced its electric motors

Monday, March 21, 2022 | Chimniii Desk

To set themselves apart from the competitors, pure electric vehicle manufacturers have implemented a variety of techniques. Tesla manufactures many of its components in-house, including the electric motors in its vehicles. Even Lucid Motors, which is still scaling up production of the Air, has been bragging about how small and efficient its electric motors, which were also created in-house, are. Rivian, on the other hand, seems to have taken a different approach.

Credit: IHS Markit Advertisement

Advertisement

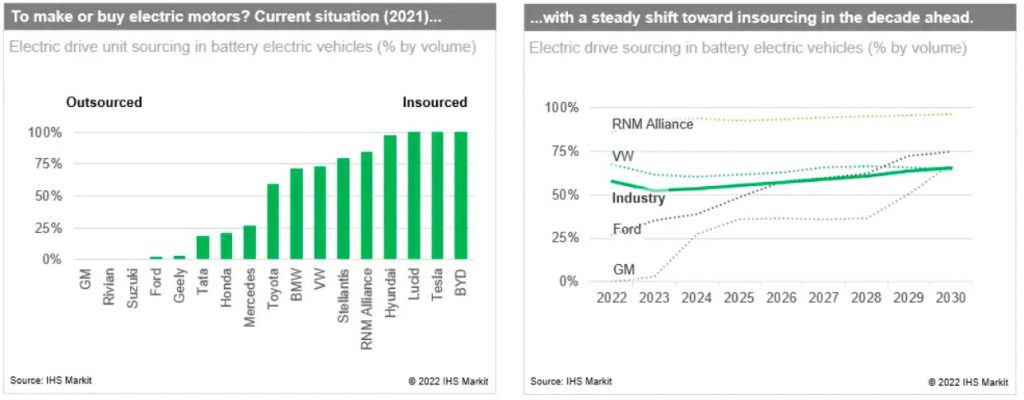

IHS Markit, an information service company, examined many automakers' motor sourcing strategy, particularly in light of the advent of the electric car market. According to the firm's report, established electric car manufacturers like Tesla regard electric drive units as critical to their efficiency and a possible source of competitive advantage. The new electric motors in the Tesla Model S and Model X Plaid, which have carbon-sleeved rotors, are an example of this.

Advertisement

It's a technology that Tesla developed and eventually built in-house, and it gives the Model S and Model X Plaid a leg up on their similarly priced competitors. Lucid is the same way, with the business putting a lot of effort into making their motors as small and efficient as possible. Some senior automakers, such as General Motors, have chosen to obtain their electric motors from Tier 1 suppliers like Bosch.

Rivian may be considered an outlier in IHS Markit's study. This was due to the fact that the electric truck manufacturer first outsourced all of its electric drive units, allowing the company to market products faster. Rivian, like rivals Tesla and Lucid, is building its own electric motors, implying that the business would likely follow an insourced strategy in the future. IHS Markit, on the other hand, predicted that insourcing will become more common in the future decade.

"In the following decade, we expect a continuous shift toward electric drive insourcing, fueled in part by US OEMs." However, outsourcing will continue to make sense in a variety of situations. Rivian, for example, initially outsourced its electric drive, which aided in the launch of its first model, before building its own. Tier 1s are still seeing considerable volume growth in this market, as evidenced by BorgWarner's recent acquisition of motor supplier Santroll. Electric drives may never be totally insourced by carmakers. "As established as the internal combustion engine is, the industry is 90% insourced, with 10% of engines sourced externally," according to IHS Markit.

Rivian may still be ramping up its car deliveries, but the firm has already demonstrated that it is willing to change with the market. Rivian CEO RJ Scaringe recently revealed at the company's Q4 and Full Year 2021 earnings conference that Rivian would be employing nickel-free lithium-iron-phosphate (LFP) cells for its Amazon delivery vehicles, after nickel costs skyrocketed due to the ongoing conflict in Ukraine. Given that Rivian's Amazon delivery trucks will likely account for a significant chunk of the company's production output in the near future, this is rather outstanding.

Advertisement